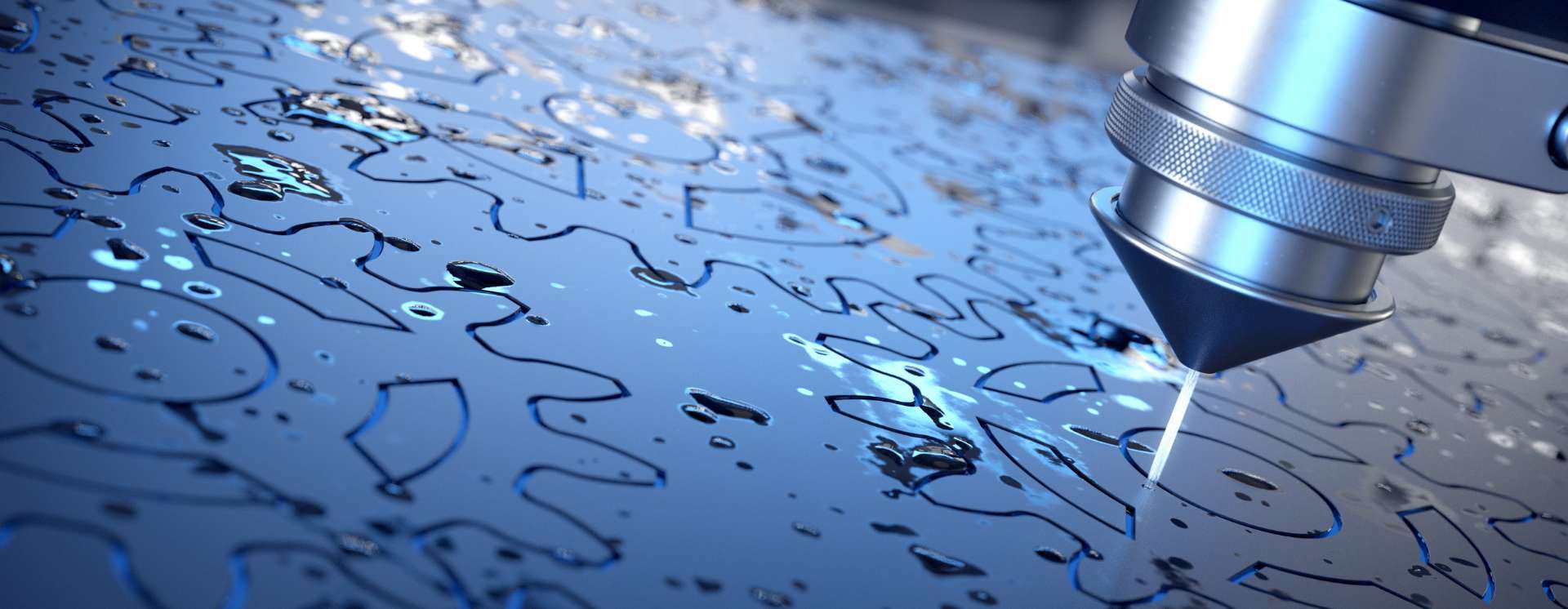

Cutting Services

Remcon’s waterjet cutting produces a better edge cut without interruption. It not only handles slots and through-cuts, but the cut can be initiated at any point on the workpiece.

Why Use Waterjet Cutting?

- There is no heat affected zone:

- No microcracking.

- Often eliminates deburring, grinding.

- Parts do not distort.

- No internal stress build up.

- We can cut heat treated material.

- Material utilization improves:

- The jet profiles vs making chips.

- Usable drops, not chips.

- Nesting and line-to-line cutting work – no heat affected zone.

- Secondary machining costs are lower:

- Cutter life is longer & feeds higher.

- Net shapes generated.

- Piercing cuts, no need for start holes – no heat affected zone.

Quality of Cut

- Sharp inside corners are easily achieved

- Clean holes are pierced and contoured

- Deburring is often not required

- Pinpoint contouring saves material

Remcon’s waterjet cutting creates no high temperatures, therefore there is little or no change in the physical properties of the material being cut.

No Heat Means…

- No slag and minimal burr

- Heat treat is not changed

- Easier machining of blanks

- Longer fatigue life

Waterjet Target Materials

Abrasive Jet:

- Titanium, Inconel, Nickel

- Aluminum, Brass, Copper

- Composites

- Bonded, Multi-Materials

- Clutch Plates, Brakes

- Rubber on Metal

- Metal on Metal

- Heat Treated Metals 35-55 RC.

Water Only:

- Cured Rubber, 30-90 Durometer.

- Plastics, Fiberglass, PVC

Remcon’s CAD/CAM software system provides prompt and precise coordination of your product’s design with its automated manufacture.

CAD/CAM

- Shapes cut directly from customer computer files

- Freehand artistic contours are scanned accurately

- Cutting programs are not separated from user engineering specs

- Redrawing is minimal, errors are reduced, traceability is held

- Nesting software improves material utilization

- Engineering changes are made promptly

Cutting Equipment and Services

- Cutting Services:

- Fixed price – short or long run

- Annual Contracts

- Process Development – per day

- Operator Training

- Cutting cost optimization

- Equipment Offered:

- Water subsystems-Intensifiers, Starters, Plumbing and Heads

- Technical Services:

- Training – Maintenance – Operation (in-house or at your facility)

- Installation

- Special Repair and Parts Programs

- Cost Reduction Programs